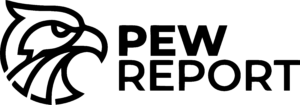

Imagine a suppressor so beastly it tames the thunder of a .50 BMG round, all forged from the wizardry of 3D printing—no welds, no seams, just pure additive manufacturing magic pushing the boundaries of metal and physics. Paul Fletcher of Fletcher Rifle Works unveiled this monster to BallisticAviation, a titanium behemoth designed for 2026 that doesn’t just quiet the big gun’s roar; it redefines what’s possible when innovation meets the Second Amendment. At a time when ATF red tape strangles traditional manufacturing, Fletcher’s crew is sidestepping the bureaucracy with homegrown tech, printing cans that could drop sound levels to whisper-quiet while handling pressures that would crumple lesser designs.

This isn’t just a shiny gadget—it’s a seismic shift for the 2A community. 3D printing democratizes suppressor tech, letting garage gunsmiths compete with corporate giants like SilencerCo or Dead Air. We’ve seen it with pistol cans like the Print-a-Sig, but scaling to .50 cal? That’s next-level, proving additive manufacturing can handle extreme heat, blast, and backpressure without the multi-thousand-dollar tooling costs. Implications are huge: cheaper, customizable suppressors mean more law-abiding shooters going hearing-safe on everything from Barretts to belt-feds, potentially flooding ranges and eroding the suppressors are for criminals myth. Fletcher Rifle Works is lighting the fuse on a suppressor revolution, where Form 1 eFiles meet FDM printers, and the only limit is your imagination (and maybe your printer’s bed size).

For the pro-2A warrior eyeing black rifle Sundays or long-range plinking, this signals the future: suppressors as ubiquitous as slings, with 3D tech bypassing NFA wait times and costs. Keep an eye on Fletcher—they’re not just building cans; they’re building the arsenal of freedom, one layer at a time. Who’s ready to print their own .50 silencer empire?